Remote surveillance of mission-critical processes increases productivity by ensuring low downtime by removing failing equipment before it breaks down. Employee safety saves time lost due to injured workers. Cybersecurity is crucial in mission-critical processes and even more so as hackers become adept at attacking sensitive processes. Private networks create fortresses to keep adversaries out.

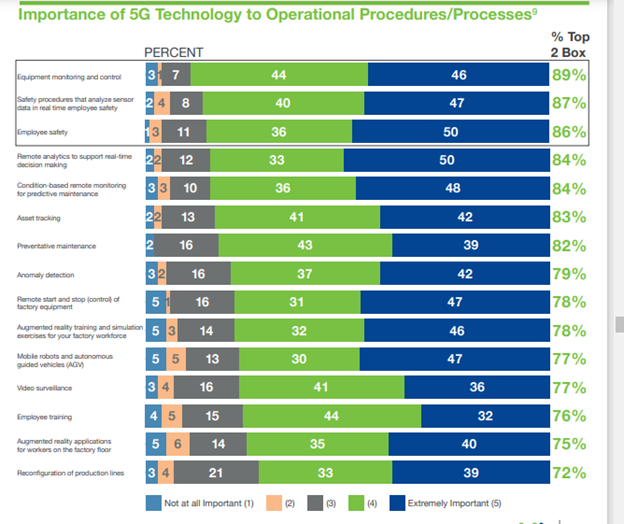

Source: Manufacturing Institue